NATURAL IMPRINT

2022-2023

Haotian Zhang, Tianying Li

Research assistants: Ryan Hung, Leo Li

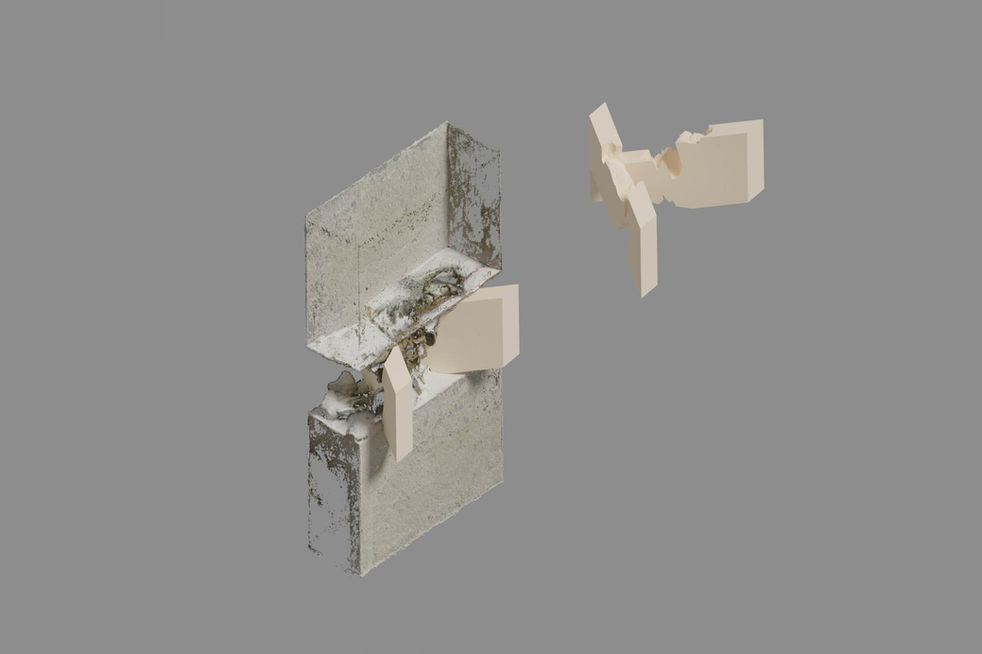

Demonstrated by a series of prototypes across scales, including a 1:1 mock-up at Saiyuen, Cheung Chau, the research explores a workflow that takes advantage of the high fidelity in 3D scanning and digital fabrication to accommodate the irregularity found in nature. Its geometric information is transcribed as “imprints” in digital models and eventually physical elements that are assembled back to the original natural condition.

As opposed to the attempt to standardize nature in mass production, this project sees the geometric complexity of nature as a given and preserves it in the later processes. In the industrial convention, natural materials such as wood or stone are first processed into elements with regular geometry and material performance so that they can be regarded as abstract lines or isotropic surfaces in the ideation of architecture. Yet, this research hypothesizes that such rationalization could be bypassed as we are now empowered by the capacity to document and fabricate in high precision. The heavy data that describes the complex condition of a found object can be relayed without the loss of fidelity in the complete cycle from survey to manufacturing.

Supported by Saiyuen.